Supply chain management is growing more complex due to a lack of synchronicity or a single missing data element, disrupting the entire chain and resulting in losses. This article discusses the advantages of machine learning and how it may help improve supply chain management.

Recently, the supply chain has faced numerous problems in terms of customer satisfaction and gain a competitive advantage. Other considerations include understanding the target audience, routes to market, and international complexity throughout the supply chain.

Supply chain management is a complicated process since consumers tend to acquire items through many channels, increasing the number of routes to market. As a result, management must be formed to ensure effective numerous supply chains.

As a result, machine learning provides a solution that improves the network’s experience, accuracy, speed, and scalability.

Machine learning is a form of technology that presents many options in an industry where every entrepreneur attempts to minimise expenses, raise total profit, and improve customer experience.

Machine learning & AI can use massive volumes of data in real-time while incorporating cloud power.

The technology can construct full machine learning-powered supply chain networks that improve understanding, foresee potential challenges, mitigate risks, and improve performance.

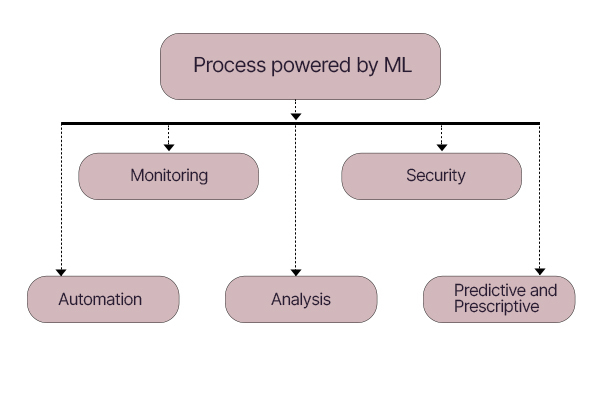

Processes Powered by Machine Learning and Emerging Technologies:

- Automation is increasing productivity.

- Monitoring is helping to advance operations.

- The analysis yields actionable insights.

- Processes are being streamlined as a result of predictive and prescriptive insights.

- Security breaches are being avoided thanks to machine learning.

Automation is increasing efficiency.

Valuable insights can assist in addressing data crunch, planning for issues, and automating procedures to improve productivity.

ML-based algorithms will be the backbone of next-generation logistics, helping to solve complex data problems and cost and delivery inefficiencies. ML can also provide insights on the automation that can provide the most substantial-scale advantages.

This technology provides supply chain operators with more substantial insights into how businesses may improve supply chain performance. Also, anticipate logistics costs and performance abnormalities before they arise.

Analysis Produces Actionable Insights.

Advanced analytics technologies are transforming data into actionable insights to assist organisations in understanding the reasons for specific changes occurring.

It also predictions errors, which can assist reduce issues by up to 50% using ML approaches.

Sales that are missed due to insufficient inventory can be planned with ML analytics.

ML is Used to prevent security breaches.

“68% of responding executives whose organisations had “major” breaches now believe that these incidents could have been averted by more mature identity and access management policies,” according to Digitalist.

Globally, organisations are increasing their investments in security processes.

Unfortunately, this investment is not proportionate to genuine security concerns and their recognised sources.

According to surveys, solutions like network antivirus, malware detection, VPNs for torrenting, and website firewalls continue to garner the most significant investment, even though the most common source of data breaches is the misuse and abuse of user credentials.

ML is laying the groundwork for preventing privileged credential abuse, preventing security breaches throughout supply networks.

Companies can reduce cyber-attack surfaces by adopting a low privilege or low authorisation approach.

This enhances audit and compliance visibility while also lowering the risk, complexity, and expenses of running a modern, hybrid enterprise.

Two-thirds of those polled said their company had been the victim of a software supply chain attack.

10 Ways that ML Can Transform Supply Chain Management

Predictive Analytics

Machine learning models may assist firms in reaping the benefits of predictive analytics for demand forecasting. These machine learning algorithms are particularly adept at detecting hidden trends in past demand data. Companies can also use ML in the supply chain to see issues in the supply chain before they cause a business interruption. A solid supply chain forecasting system guarantees that the organisation has the resources and information necessary to respond to emerging difficulties and hazards. Furthermore, the effectiveness of the response is proportional to how rapidly the organisation can respond to problems.

Robust Management Necessitates the Use of Automated Quality Inspections.

Manual quality inspections are typically carried out at logistics hubs to inspect containers or shipments for any harm that may have happened during transportation. However, the rise of artificial intelligence and machine learning has widened the scope of supply chain quality inspection automation. Approaches based on machine learning enable automated analysis of flaws in industrial equipment and image recognition-based damage identification. The benefit of these sophisticated mechanical quality inspections is that customers’ danger of giving defective items is reduced.

Making Manufacturing Planning More Productive

Machine learning has the potential to assist simplify production planning. Businesses can use machine learning models and techniques to train complicated algorithms on current production data, helping to uncover possible inefficiencies and waste. Furthermore, machine learning in the supply chain is essential in creating a more flexible ecosystem that can efficiently deal with any form of disruption.

Warehouse Management

Warehouse and inventory-based management are frequently linked to efficient supply chain planning. By utilising the most current demand and supply information, machine learning can continuously improve a company’s efforts to provide the required quality of customer service at the lowest cost. In addition, machine learning in the supply chain, with its models, methodologies, and forecasting skills, may also address the issue of both under and overstocking, completely changing your warehouse management.

Errors in Forecasting are Reduced

Machine learning is a robust analytical approach that may help supply chain businesses process massive amounts of data. Because of telematics, IoT devices, intelligent transportation systems, and other powerful technologies, ML in the supply chain ensures that vast volumes of data are processed with the most incredible variety and unpredictability. This enables supply chain organisations to collect a lot more insight and make more accurate estimates.

Advanced Last-Mile Tracking

Last-mile delivery effectiveness can directly impact various sectors, including customer experience and product quality, making it a critical component of the entire supply chain. According to research, last-mile delivery accounts for 28% of overall delivery expenses in the supply chain. By adding multiple data points, such as how individuals input their addresses and the overall time it takes to deliver things to certain areas, machine learning in the supply chain may give considerable benefits. Machine learning can also help speed up the process and provide clients with more up-to-date information about the status of their shipments.

Recognition of Visual Patterns

Machine learning excels at visual pattern recognition, which offers up a plethora of new opportunities for physical asset inspection and maintenance throughout a whole supply chain network. Machine learning is particularly effective in automating inbound quality evaluation across logistics hubs, isolating product shipments with damage and wear using algorithms that rapidly search for similar patterns in large data sets.

The Future of Supply Chain

There is a lot of variability in the supply chain sector. As a result, the processes are growing more onerous, and managing massive amounts of data is becoming more complex.

As a result, controlling the supply chain network is becoming increasingly crucial for efficient operation, including accurately forecasting demand, spotting patterns, building safe routes, and much more.

Machine learning may not produce immediate results, but it will provide long-term benefits to the supply chain. As a result, organisations must plan for the future and begin utilising machine learning technologies.

Investing in machine learning, artificial intelligence, and related technologies can help your firm dramatically boost profitability and resources in the future. In addition, businesses will have better plans as a result of ML, resulting in fewer inefficiencies.